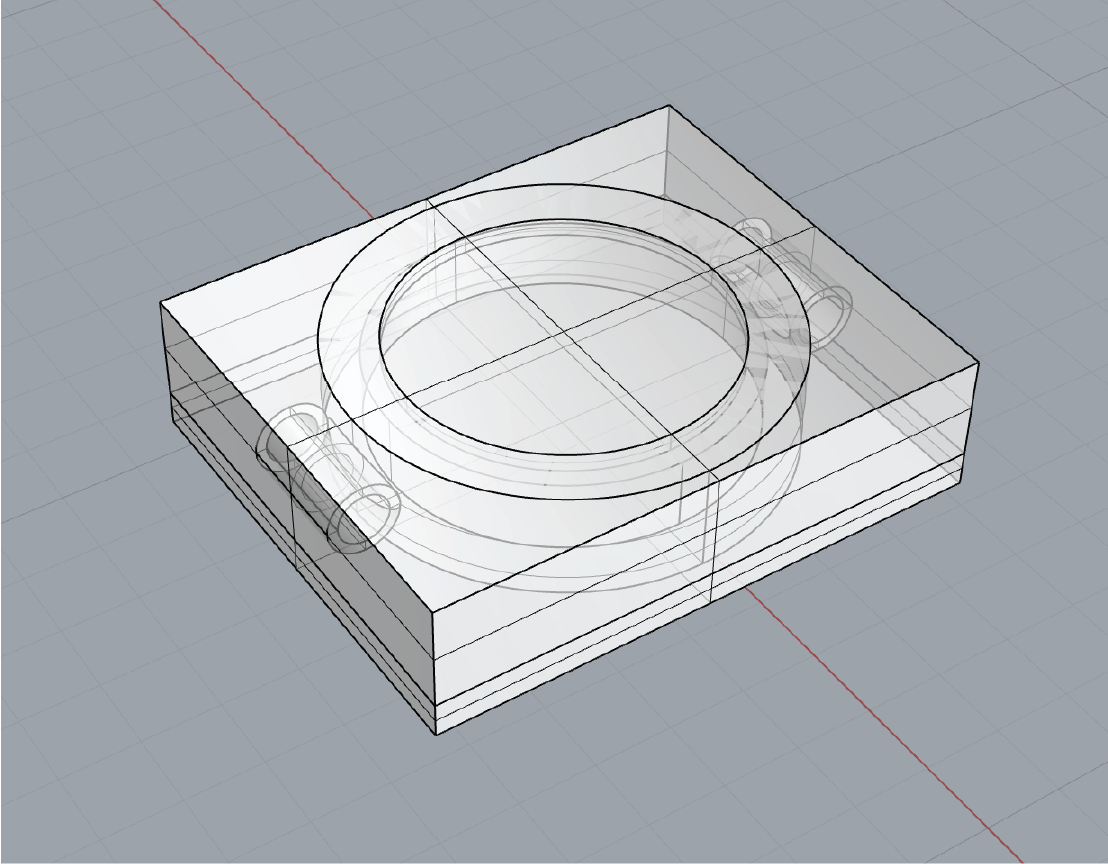

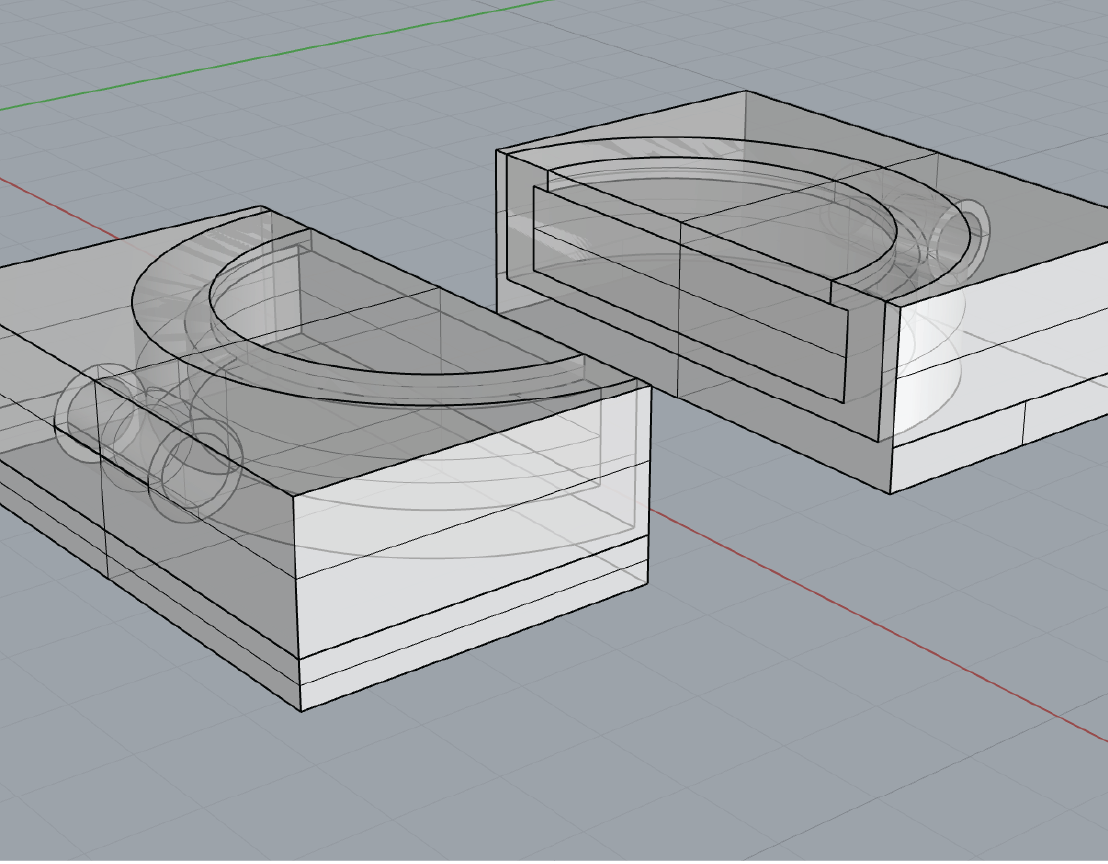

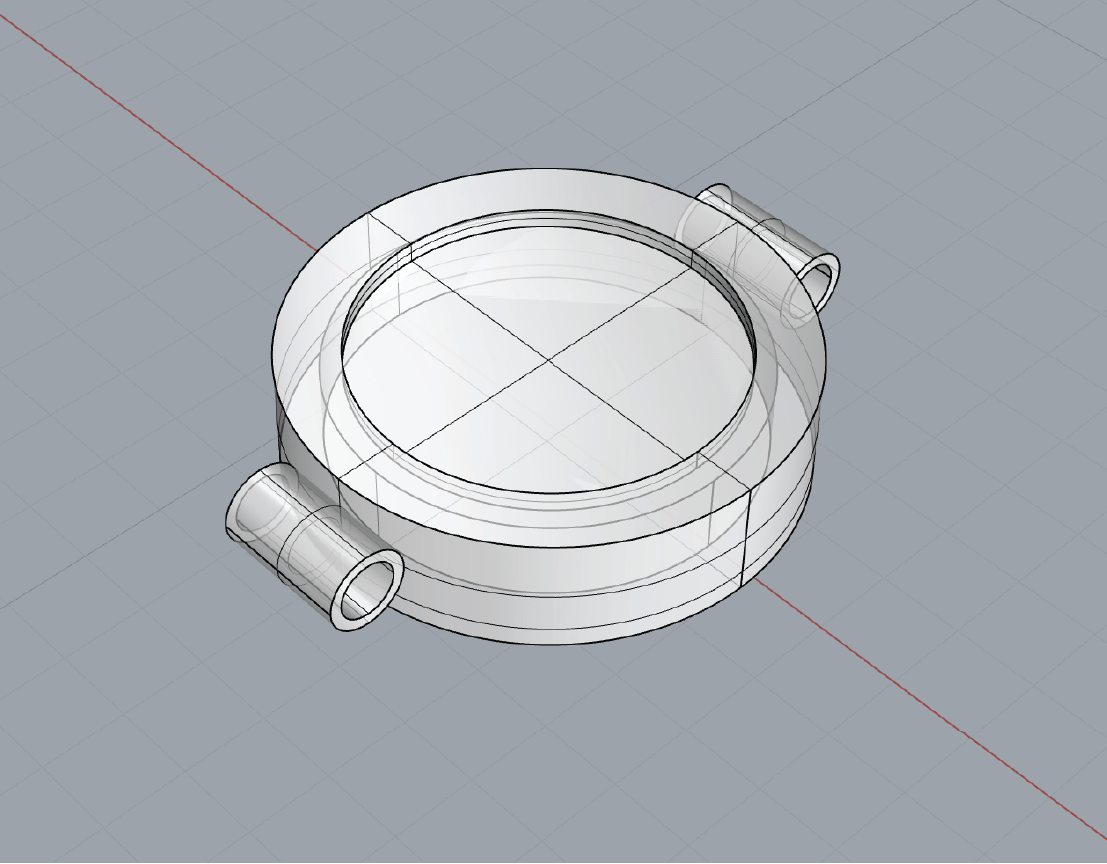

INITIAL DESIGN.

I started by defining the shape I wanted to obtain with the mold. In my case I wanted to design a piece which could contain an algae biomaterial which one could wear and while swimming with it it could dissolve into the water and release probiotics specially for coral regeneration.